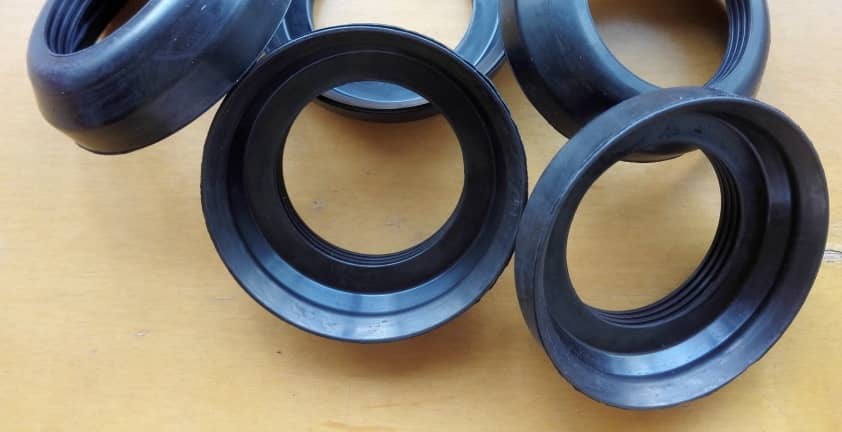

Industries and consumers alike are looking for solutions to lessen their ecological footprint at a time when environmental sustainability is becoming increasingly important. The rubber seal is one part that’s sometimes disregarded but nevertheless has a big impact on environmental sustainability. These modest devices are vital in many different applications, ranging from domestic appliances and plumbing to the automobile and aerospace sectors. Rubber seals not only enhance the performance and longevity of products but also contribute significantly to environmental conservation. The several advantages of employing rubber seals for the environment are examined in this article.

Energy Efficiency And Conservation

Rubber seals’ capacity to increase energy efficiency is one of their main environmental advantages. In many industrial and household applications, rubber seals are used to prevent the escape of air, water, or other fluids. By maintaining a tight seal, these components help ensure that energy is not wasted. Rubber seals, for example, stop heated or cooled air from escaping HVAC systems, and as a result, less energy is needed to keep the air at the right temperature. This lowers greenhouse gas emissions related to energy production as well as energy consumption.

Reducing Resource Consumption

Rubber seals contribute to the conservation of natural resources by extending the lifespan of machinery and equipment. Rubber seals assist preserve the integrity of various components by preventing leaks and decreasing wear and tear, which results in fewer replacements and repairs. This durability translates to a reduction in the consumption of raw materials needed to manufacture new parts. In industries such as automotive manufacturing, where rubber seals are extensively used in engines, transmissions, and other critical systems, the extended lifespan of these components can lead to substantial resource savings.

Preventing Pollution

Another significant environmental benefit of rubber seals is their role in preventing pollution. Hazardous materials may leak out of home appliances or industrial machines and into the environment. For instance, oil leaks in hydraulic or car engines can contaminate water and soil supplies, endangering human health and ecosystems. Rubber seals, by ensuring a tight seal, prevent such leaks and mitigate the risk of environmental contamination. Additionally, in plumbing systems, rubber seals prevent water leaks, conserving this vital resource and reducing the strain on water treatment facilities.

Waste Reduction

The durability and effectiveness of rubber seals contribute to waste reduction. By enhancing the longevity of products and minimising the need for frequent replacements, rubber seals reduce the amount of waste generated. This is particularly important in industries where equipment and machinery are subject to rigorous use and harsh conditions. High-quality rubber seals can withstand extreme temperatures, pressures, and chemical exposures, ensuring that equipment remains operational for longer periods. As a result, the environmental impact of waste disposal is decreased because fewer abandoned components wind up in landfills.

Supporting Sustainable Manufacturing

The production of rubber seals has also seen advancements in sustainable manufacturing practices. Rubber seals are now produced by numerous firms utilising environmentally friendly materials and procedures. For instance, natural rubber derived from sustainably managed rubber plantations is being used as an alternative to synthetic rubber. Additionally, recycling programs for rubber products are gaining traction, allowing used rubber seals to be repurposed or recycled into new products. These programmes support a more circular economy and lessen the negative environmental effects of the production of rubber seals.

Reducing Carbon Footprint

The utilisation of rubber seals has the potential to mitigate the carbon footprint of many sectors. By enhancing the efficiency and longevity of machinery and equipment, rubber seals reduce overall energy consumption and resource use. Lower carbon emissions from the manufacture, shipping, and disposal of replacement parts follow from this. In the automotive industry, for example, rubber seals used in engines and transmissions help improve fuel efficiency, leading to reduced carbon emissions from vehicles. Similarly, in manufacturing plants, rubber seals in hydraulic and pneumatic systems contribute to more efficient operations, further lowering carbon emissions.

Water Conservation

Water conservation is another critical environmental benefit of rubber seals. Rubber seals are essential for stopping water leaks and guaranteeing effective water use in home, commercial, and agricultural settings. Irrigation systems, for instance, rely on rubber seals to maintain a consistent flow of water, minimising wastage. In household plumbing, rubber seals in faucets and pipes prevent leaks that can lead to significant water loss over time. By conserving water, rubber seals help alleviate the pressure on water resources, which is especially important in regions facing water scarcity.

Conclusion

Rubber seals may seem like small and inconspicuous components, but their environmental benefits are substantial. Rubber seals are essential for achieving environmental sustainability because they reduce waste, minimise pollution, and improve energy efficiency and resource consumption. As industries and consumers continue to prioritise eco-friendly practices, the importance of high-quality, durable rubber seals will only grow. By choosing rubber seals, we not only enhance the performance and longevity of our products but also contribute to a healthier and more sustainable planet.